- reFuels are free of undesirable by-products such as sulphur or nitrogen compounds.

- The structure and composition of the reFuels can be adjusted and optimized for the specific application, particularly with regard to combustion efficiency and the formation of local emissions.

- The project's focus on hydrocarbon components means that reFuels can be integrated into currently used fuels.

The high energy density of liquid fuels and their ease of storage and transportation are retained with reFuels. - The existing transport infrastructure and logistics as well as the application technologies can be used as long as the fuels remain within the existing standards.

The use of existing infrastructures and renewable energies for the production process of reFuels reduces CO2-emissions in the existing fleet with CO2-neutrality as a clear goal.

What are reFuels?

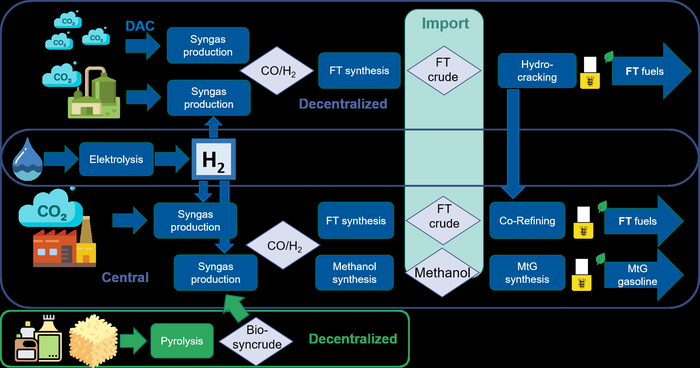

Regeneratively produced fuels - so-called reFuels - have the same energy density as fossil fuels and are therefore, alongside other measures such as the expansion of electromobility, a promising path towards CO2-neutral mobility. reFuels can be produced from carbon-containing residues from agriculture and forestry, from industrial and municipal waste as well as through the direct conversion of CO2 and sustainably produced hydrogen.

How are reFuels made?

In the bioliq® plant on KIT's North Campus, for example, straw is processed to produce synthetic gasoline from second-generation biomass, so-called advanced biofuels. Unlike first-generation biofuels, the synthesis of these advanced fuels from biomass does not compete with the cultivation of food and animal feed on agricultural land.

Find out more about bioliq® here.

In the neighboring KIT Energy Lab 2.0, eFuels are produced from the electrolysis of water with the help of regeneratively generated electricity andCO2. The main target is kerosene, but diesel and gasoline fractions are also produced. TheCO2 produced during the combustion of eFuels is offset by usingCO2 from the ambient air or from biogenic sources for their production.

This presentation illustrates the synthesis processes. Find out more about the Energy Lab 2.0 here.

%20KIT_Markus%20Breig%20und%20Amadeus%20Bramsie-3.jpg)